Archive for May, 2008

Heber South enters Commercial Operation

Photo Credit: EERE

Last week Ormat announced that the 10MW Heber plant had been commissioned. This brings total output of the Imperial Valley facility to 92MW and boosts Ormats portfolio to over 400MW for the first time. Ormat is slated to announce first quarter earnings tomorrow (May 6th.)

What’s in a Name?

If you think that this entry will be about literature, you’ll be disappointed. It’s about the noise being generated right now around various thermodynamic cycles where heat is converted to work. Recently we’ve seen an upswell of interest in the Kalina Cycle harvest method and a number of companies have been chartered and funded to produce harvest systems for a variety of heat sources (like Exorka and Kalex.)

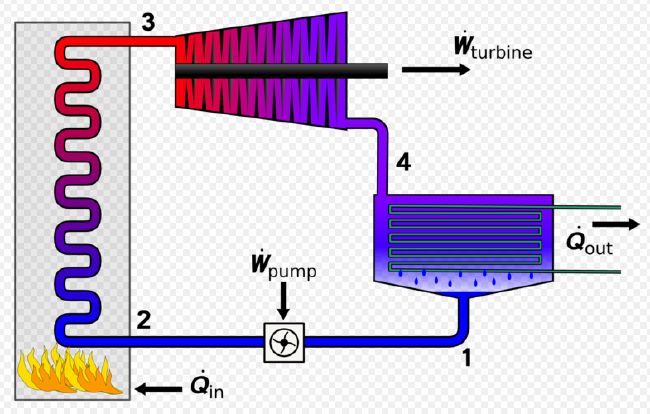

But just what is Kalina Cycle? Before we answer that, we need to take a look at basic Rankine Cycle (or sometimes called Carnot Cycle) harvest. It is a 4 stage process by which a working fluid is pressurized, heated to prompt phase change from liquid to gas, expanded through a harvest device (typically a turbine,) and then condensed. The cycle is closed loop in nature and forms the basis for virtually all electricity generation involving heat (geothermal, solar thermal, natural gas, coal, and nuclear – for the US, that’s 90+% of generation.)

Attribution: Andrew Ainsworth

A variation on theme is Organic Rankine Cycle which follows the same process as Rankine Cycle with the principal difference being the composition of the working fluid. In straight RC the working fluid is most often water. In ORC the working fluid tends to be a stable compound with a relatively low boiling point (i.e. isobutane or isopentane.) This is less efficient than RC but can harvest energy from heat sources from 75-150C where RC requires 250C and higher temperatures to function well.

Thus we come to Kalina Cycle, really a variation on ORC (and thus RC.) It was proposed by Alexander Kalina about 20 years ago. KC follows the same process as RC, but again changes the composition of the working fluid from a single stable compound with a low boiling point to a two part working fluid (most often ammonia/water mixture) which can, under certain circumstances, increase the efficiency of ORC harvest of relatively low temperature resources.

Of the 3 related conversion cycles, RC and ORC are in wide use today. Kalina Cycle is still gaining steam, so to speak. 2 comments

More Small Wind

Attribution: TechnoSpin

Small wind seems to be gaining momentum. Recently, TechnoSpin secured an $8M Series A investment to scale up the manufacture of their line of small-scale wind turbines. The technical breakthrough for Technospin was in blade design leading to cut in and production at slower speeds than traditional turbines (3-4/m/sec range.)

The company offers 4 variations of turbine with rotor diameters ranging from 1.2 to 6m and peak power output ranging from 0.2 to 3.8kW. Two distinct offers from the company include the SeaSpin microturbine for electricity production in maritime environments and WaterSpin, a pumping microturbine for agricultural environments. The other two offers are for residential and small business use for straight electricity generation.

We will be curious to see how the small wind segment shakes out, there are clearly opportunities here if a company can hit the right price/performance/convenience ratio.