Archive for February, 2007

KKR led consortium acquires TXU

In what can only be described as a mega-deal, investment firm Kohlberg, Kravis, Roberts, & Co. are paying a 15% premium over market close, $69.25 per share, to take TXU Corp private. The $31.8 billion dollar deal is the largest ever to take a company private.

Why do we care? Simple, as a consequence of the takeover, TXU’s planned 11 mega-coal plants will be reduced to 3 as a result of the acquisition and stronger environmental policies are likely to be enacted. The reduction will displace some 56 million tons of carbon emissions, equivalent to preventing 10.2 million new cars from appearing on the road.

This is an interesting development to be sure. Let’s hope the focus shifts from coal to other, less polluting generation mechanisms as a private company. But axing 8 planned coal plants is a good start.

If you liked this entry, Digg It!

Technorati Tags: Energy | Megadeal | TXU Buyout

More investment in clean tech

CalPERS (the California Public Employee Retirement System) doubled down earlier this week adding $400M to the $200M already set aside for clean tech investments. This is encouraging news as it means a large investor seeking outsized returns is seeing something they like in the clean tech space as well as the simple fact that $400M more is available to entrepreneurs in the segment.

Way to go CalPERS, you’re demonstrating great leadership. Thanks to John for the pointer to this event.

If you liked this entry, Digg It!

Technorati Tags: Energy | Clean Tech | Investment

Silicon-free Solar

Recently I ran across a reference to the Swiss company Flisom which is a 2005 spinoff of ETH Zurich (The Swiss Federal Institute of Technology.)

Traditional photovoltaic (PV) cells use monocrystalline silicon wafers to capture photons in sun light to excite electrons which are then directed to a conductor resulting in direct current. These PV cells are the prevalent technology installed in the marketplace today. Another variation on theme is to coat a silicon substrate with some sort of PV chemical mixture which then performs essentially the same process as pure silicon PV cells. The issue with these approaches is cost, manufacturing and material.

The latest research has revolved around nanocrystal, polymer, and photoelectrochemical cells. That’s where Flisom comes in, they seem to have figured out how to use the photoelectrochemical approach on a plastic foil substrate to harvest sunlight and convert it to direct current. The Flisom approach uses the Cu(In,Ga)Se2 compound (commonly called CIGS) sandwiched between a layer of Zinc Oxide (ZnO) on the top and Molybdenum (Mo) on the bottom. See a cross section of the material in the image below:

The efficiency demonstrated right now is 14%, which is pretty good for an emerging technology. If they can perfect this approach, the solar electric power landscape will change as the material can be cost effectively produced and all of the sudden common items like windows can become solar arrays inobtrusively and cheaply. That would be pretty cool…

If you liked this entry, Digg It!

Technorati Tags: Energy | Solar | Photoelectrochemical

Geothermal Co-production with Petroleum?

Here’s something interesting you may not know: when harvesting oil, there is often “waste water” mixed in the substance coming out of the hole, frequently the water is under pressure and hot. While at the Stanford Geothermal Conference last month, Mark Milliken covered this information during his talk.

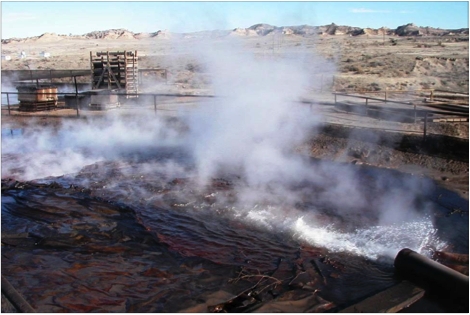

Waste Water Discharge at Naval Petroleum Reserve #3

The Naval Petroleum Reserve #3 is really part of the Department of Energy’s Rocky Mountain Oilfield Test Center. As such, it’s not bound by the economic realities of having to produce or else and can experiment a bit with new drilling techniques as well as ponder the question: “what should we do with all this hot water?”

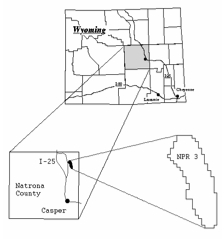

NPR #3’s location in Wyoming

At this particular site, some 6.4 million liters (1.7M gal) of 87°C (190°F) water is discharged per day as part of their oil production. This water is routed into a cooling pond and then released into Little Teapot Dome Creek when the water has cooled sufficiently. Curiously, the amount of oil produced from this activity is around 48,000 liters (12,600 gal) per day. As you can see, far more water is produced per day than oil! The raw power equivalent of this water is estimated to be 22MW, or enough to power some 25,000 homes per year. But, a small fraction of that raw power is available for harvest with existing technologies.

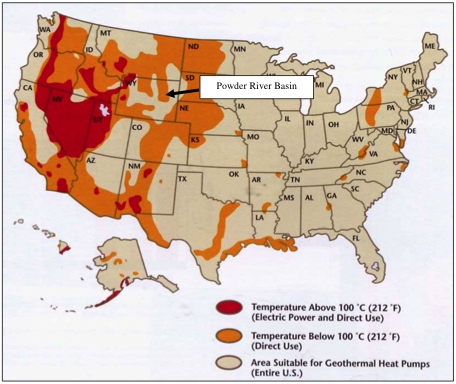

Where does all this hot water come from? The water is hypothesized to come from the Big Horn Mountain range where it soaks into the earth and descends to a series of hot rocks. It then migrates to the Powder River Basin and pours into fissures in Ten Sleep and Madison Limestone layers where it is extracted during petroleum operations. The heat map below will provide some context for how the NPR #3 site fits into the overall estimated heat flow at a 3km depth.

US Heat Map 3km depth

Using binary systems to extract the heat from this water could easily yield a couple of hundred kilowatts in a binary generation scheme. These units need around a 50°C (120°F) difference in temperature between the ambient temperature of production and the resource. It would seem likely that this could be established and maintained at this site and many others. It’s interesting to see this type of exploration underway and it could provide additional benefit (both ecologically and economically) to take advantage of this “free” by-product of an existing activity.

If you liked this entry, Digg It!

Technorati Tags: Energy | Geothermal | Oil

Multi-axis turbines?

Traditional wind systems have had either a horizontal axis with a single blade (95+% of what is in use today) or vertical axis with a single blade (think large egg beater anchored to the ground.) A company called Mass Megawatts Wind Power Inc. is advancing the application of multi-axis vertical turbines, that is many blades mounted vertically in a box-like array around 20 meters off the ground.

The thinking behind this technology is that with more smaller blades, lower wind speeds will be able to output power than in traditional horizontal turbine systems. The design has two generator modes, one 7.5 kilowatt that cuts in at under 4.5 meter/second (~10mph) and another 22.5 kilowatt that cuts in at 6.25 meters/second (~14 mph.) Each unit has 32 generators attached to 32 shafts with blades. That means in a 6 m/s wind, 100% output would be around 864 kilowatts/hour and in a 8 m/s wind, 100% output would be 2,592 kilowatts hour. The image above is a smaller prototype system.

Wind systems rarely operate at 100% capacity, in fact, the average capacity factor is 30% across the installed wind farms. If we take this into account, the MAT system would produce somewhere between 2,267 and 6,811 megawatt hours per year depending upon which generator has the dominant share of time in action. At the prevaling wind rate of $45/MWh, that gives a revenue spread per unit per year of $101,015 on the low end to $306,495 on the high end. The acquisition and construction cost of each unit is estimated (by Mass Megawatts) to be $210,000 per unit. If the MAT unit performs as above and maintenance costs don’t kill it, it might be economically viable.

The science of harvesting kinetic energy from the wind is pretty straight forward, the density of the air moving through the swept area of the turbine at some speed dictates how much energy can be harvested. The formula is: Power = 0.5 x Swept Area x Air Density x Velocity3. Without accurate measurements of the blades on the MAT we can’t make the calculation, but at first blush, the swept area doesn’t look sufficient to produce the stated power levels. This is physics, the equation has to solve so if the area is smaller, then the velocity has to increase and/or air density has to increase.

The other claim made by the MAT folks is that the maintenance costs are lower. I’m high skeptical of this as basic physics dictates the more moving parts an object has, the more opportunities for things to break. In a traditional horizontal turbine there is one blade assembly, one gearbox, one turbine etc you get the picture. On the MAT, there are 32 turbines, 32 shafts, who knows how many blades; it’s at least 32x more likely to experience failure in a given time frame. Now, with the horizontal turbine, a failure tends to be complete. In a MAT, that’s not necessarily so, if 1 shaft/generator/blade combo goes, theorhetically, the other 31 are still in business.

I’m all for experimentation and open minded that breakthroughs can and do happen, but I don’t think we’re seeing one here. A part of me hopes that there is something to this, but the evidence seems to suggest that this design introduces more problems than it solves. We’ll see as Mass Megawatts installs their wind farm, the business plan calls for 100 units to be installed this calendar year. Proof will be in production and we’ll be able to see that as a result of their quarterly reports. We’ll be watching with interest.

If you liked this entry, Digg It!

Technorati Tags: Energy | Wind | Multi-axis Turbine