HFR, It’s Hot

Attribution: Geodynamics

For those of you not in the know, HFR is hot fractured rock. The latest incarnation of HDR (hot dry rock) or EGS (enhanced geothermal system.) Pioneered in the early 1970’s at the Fenton Hill, New Mexico site, HDR is the process of introducing water into a known hot rock bed, inducing fractures in that rock bed to create a reservoir, and then harvesting the steam that results from the contact between the super hot rocks and the water through production wells.

The Fenton Hill project was shut down years ago, but the concept has taken on new life in Australia where no fewer than 32 companies are now working in the Cooper Basin to find a way to mine the heat, convert it to electric power, and transmit it to consumers.

Here in the US, the HFR et al view was featured prominently in an exhaustive report assembled by MIT and published last year stating that if commercial drilling could cost effectively reach the 10km depth, over 100,000MWe of geothermal electricity generation would be accessible to harvest. Australia though, is really taking this to heart as the Cooper Basin is an enormous, known hot granite area with temperatures in excess of 250C at 4km depth. Also, the basin has a “cap rock” geology, meaning that once a system is stimulated, the steam won’t leak to the surface, it needs a clear path, the kind that is created by drilling a production well.

Attribution: Geodynamics

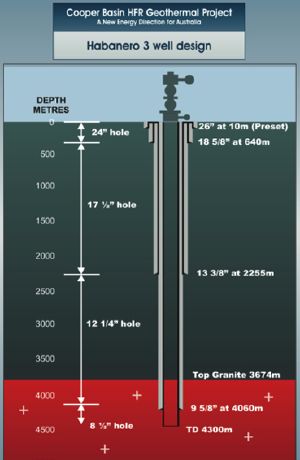

Geodynamics, Limited is a leader in working HFR project toward commercial viability and operation. To date, Geodynamics has drilled three deep wells, Habanero 1, 2, and 3 to depths of over 4km. Recently the company announced that it had been able to successfully inject water into the reservoir, increase the fracture size, and produce steam at pressures of over 14MPa (~2,000 psi) and flow rates of 27kg/second. This is sufficient to supply their 1MWe test harvest plant planned for installation and operation this year.

The next step for Geodynamics is to drill 9 wells (4 injection and 5 production) to supply a 50MWe electricity generation facility and advance the transmission projects to bring the power to market. Finally, the company plans to scale up by adding nine more 50MWe facilities, bringing the project’s total output to 500MWe by 2016.

While this is a great vision and by all accounts, Geodynamics and others are making progress toward realizing the vision, there are challenges and risks. One of the biggest challenges and risks has to do with “connectivity” – which means, when water is injected into the reservoir, is the steam from the injected water coming back out? And if so, how much of the injected water is being recovered as usable steam? These fractures aren’t highly controllable and thus in most HFR projects there is a significant shortfall between mass of injected fluid and mass of recovered steam.

Also, in this area of Australia, water is a scarce resource. Since the reservoirs that do exist in the rock naturally are not of production quality and there is little chance of refresh, the gamble is on the water in a relatively shallow aquifer holding out while Geodynamics and other companies compete for the water resource.

Even with the challenges and risks, this is an exciting and vital segment of the geothermal industry.

HT: Bruce Wilcox

Nice article Mike. I think GDY is on the cutting edge of a completely new approach to geothermal energy production. A couple points:

1. The GDY project is a LONG way from the electric grid and will require a major investment in a new power line to deliver electricity to market. This won’t be feasible until they prove they can deliver the hundreds of MW they are planning. Even if they are completely successful I think it will be a long time before they are generating revenue.

2. I have a good friend who worked at Los Alamos (on solar) when the Fenton Hill project was operating and he says that scaling in the heat exchangers due to minerals extracted from the rocks was a serious problem. GDY says they have this under control, but it remains a question for me.

3. Fenton Hill lost ~25% of the water they injected. GDY says their hot rocks are under high positive pressure so they won’t lose any water. This also remains to be seen.

4. Australia has been drilled extensively for oil and gas and there is a database of drill records including temperature so the HDR resources are pretty well known.

5. The big issue is making the new approach work and if GDY succeeds their knowledge will be a big asset. They have had major successes and big problems, including a drilling snafu that destroyed their 2nd well. They also have deep pockets backers (the largest electric utility in Australia) and major geology talent on staff so I think they have a decent prospect of success.

Thanks for the comment (and the tip) Bruce. Your points are very valid and expand on the challenges and risks mentioned in the original piece. I haven’t heard the scaling problem in the Australian projects, but that doesn’t mean it’s absent…

Very interesting indeed. I hope this will bring on more opportunities for the drilling industry that seems to be on the downslope of oil exploration. Anything we can do to keep drilling for energy is good IMO.